Roller-hearth Salt Bath Quenching Heat Treatment Production line

The salt quenching roller hearth furnace developed by Yajie is a new generation salt quenching equipment, adopts Yajie many new patents, widely used for bearing industries, automobile parts industries processed by atmosphere salt quenching Martensite and Bainite quenching.

Classification:

Products

Hotline:

E-mail:

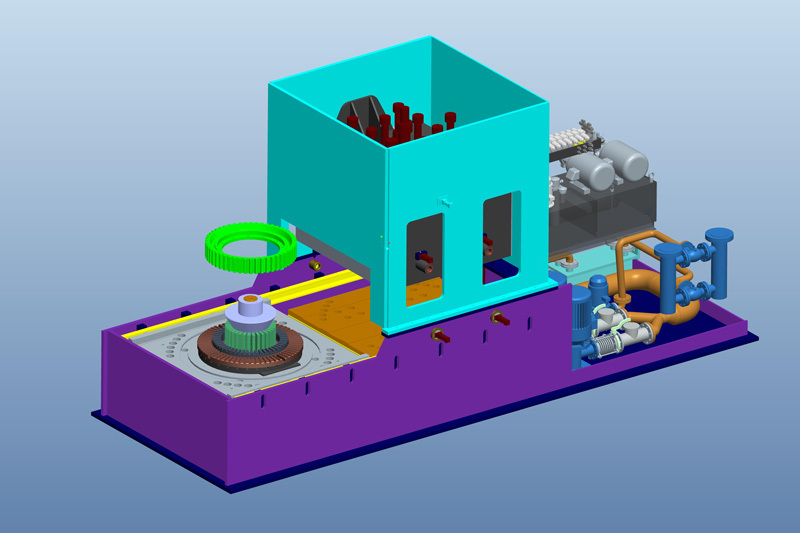

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Product General Description

The salt quenching roller hearth furnace developed by Yajie is a new generation salt quenching equipment, adopts Yajie many new patents, widely used for bearing industries, automobile parts industries processed by atmosphere salt quenching Martensite and Bainite quenching.

— Updated products for bearing industry of Martensite and Bainite salt quenching.

— Listed by Ministry of industry and information the 7th 《Energy saving mechanical and electrical equipment (products) recommendation list》

Product Structure and Character

Pre-washing machine adopts the designing of rinsing and spraying and equipped with ultrasound washing system to improve the cleaning efect.

Adopting Yajie patent roller and ceramic roller assembly, fast disassemble structure which could realize the fast exchanging of the lower rollers under high temperature. It makes maintenance more conveniently; the structure could efectively reduce the heat short cut, the energy saving result is obvious.

The selection of quenching method: designed with open quenching and closed quenching for choice, the color of parts after processed is uniform black and blue.

The patent of salt quenching and tempering in the same tank (Patent No. : ZL201410173288.2), The patent of quenching and tempering process in the same salt tank which realized the recycling of the thermal to reduce the power consumption.

The selection of tempering: Yajie’s salt quenching roller hearth furnace can customized with different tempering furnace according to different demands and products, they are quenching tempering isothermal within the same tank, roller hearth tempering furnace, chain belt tempering furnace and many more type of furnaces for choice. Yajie 3 floors roller furnace can reduce energy consumption, reduce space and ensure the uniformity of furnace temperature reliably.

| Full recovery of residual salt, zero emission, good workshop environment, environmental protection up to standards. | Heating method: Electric heating or Gas heating. |

| Visible operation, interface friendly, process setting conveniently downloading. | Tray info and process is traceable at any time and could be stored for more than 10 years, the high-end customer’s demand of products traceability could be satisfed. |

| Designed with distance maintenance function to realize equipment malfunction online diagnosing and removal which guaranties the stable production for the customers. | Developed with smart phone APP to realize real moving ofce. |

Product Specifcations

Type | Size of trays | Efective height | Working position | Cycle time | Max. load |

RRX 8-75×75 | 750×750 | 120-300 | 6-10 | Adjustable | 120kg |

RRX 8-85×85 | 850×850 | 150-300 | 6-10 | Adjustable | 200kg |

RRX 8-95×95 | 950×950 | 200–400 | 6-10 | Adjustable | 250kg |

RRX 8-125×125 | 1250×1250 | 200–450 | 5-8 | Adjustable | 400kg |

RRX 8-150×150 | 1500×1500 | 300–500 | 4-8 | Adjustable | 600kg |

RRX 8-180×180 | 1800×1800 | 400–600 | 1-6 | Adjustable | 1500kg |

RRX8-260×260 | 2600×2600 | 400–650 | 1-6 | Adjustable | 2500kg |

Heat Treatment Production Line For Roller-hearth Annealing (Normaliz-ing) In Protective Atmosphere

Product General Description

Roller-hearth Atmosphere-controllable Annealing Furnace are mainly used for atmosphere-controllable spheroidization annealing on a large scale parts of following bearing industry components: bearing ring, running pulley, steel wire rod, tubular product and etc., or forging parts of the protective atmosphere of normalizing.

Product Structure and Character

Has excellent stability and quality consistency.

The protective atmosphere can be accurately controlled during the period of annealing period, total decarburization depth is less than 0.04mm.

When used for isothermal spheroidizing annealing, the waste heat recovery system adopts our patent technology, fully utilizes waste heat energy, the electricity power consumption per product ton reaches to 160kW·h, evidently reduces production cost for customer.

Equipment layout form adopts linear type, physical separation of incoming and outgoing materials, meets high end customer’s demand, completely eradicates hidden trouble of mixed material.

Adopts intelligent energy management system, real-time records and analyses energy consumption.

Can equip video record system, real-time record scene condition, and see data by remote login method.

Product Specifcations

Type | Dimension | Cycle time | Max. load | Atmosphere |

RRN8(9)-130×120×50 | 1300×1200×500 | 40-60min | 1000kg | N2 + C3H8 |

RRN8(9)- 150×130×50 | 1500×1300×500 | 40-60min | 1250kg | N2 + C3H8 |

RRN8(9)- 150×150×50 | 1500*1500*500 | 40-60min | 1500kg | N2 + C3H8 |

Can provide customized designing as per customer demands as well.

In addition, it provides a single room protective atmosphere roller annealing furnace, which is especially suitable for batch spheroidization annealing of disk circle. There are 10 tons, 20 tons, 30 tons of various furnace types to choose from.

Pre

Pre

Pusher Furnace Heat Treatment Line

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry