Industrial Gas Deep Purification Equipment

In the controlled atmosphere heat treatment sector, natural gas (propane) has found ever-increasingly extensive application. With the demand on quality of heat treatment process becoming ever-increasingly stricter, the effect on quality of processed product produced by the sulphur adverse content in natural gas (propane) has become a public concern. The natural gas (propane) desulphurization equipment developed by Yajie provides a stable supply of natural gas with very low sulfur content.

Classification:

Products

Hotline:

E-mail:

Industrial Gas Deep Purification Equipment

Product General Description

In the controlled atmosphere heat treatment sector, natural gas (propane) has found ever-increasingly extensive application. With the demand on quality of heat treatment process becoming ever-increasingly stricter, the effect on quality of processed product produced by the sulphur adverse content in natural gas (propane) has become a public concern. The natural gas (propane) desulphurization equipment developed by Yajie provides a stable supply of natural gas with very low sulfur content.

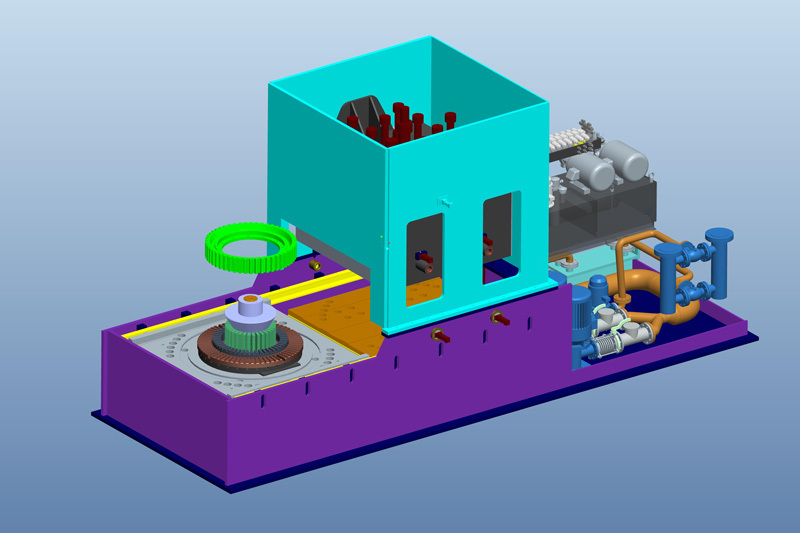

Product Structure and Character

The equipment is of a double-tank design, with one operating and the other standby for steady gas supply.

Use is made of multi-component purifying agent. Due to efective removal of organic and inorganic sulphur, the total sulphur content of the natural gas supplied is controlled below 5mg/m³.

The purifying agent can be reused with a service life of over 10 years.

The equipment can operate under normal temperature. As no heating operation is required for maintaining its normal operation, the power rate can be appreciably curtailed.

It is of a standardized design. A series of the purifying equipment in capacities of 10-150 m³/h is available.

The purifying tanks are all of internally heated design, and the regenerated heat is high in efciency and low in energy consumption and can be produced within a short time period.

It is provided with PLC system which can perform automatic leakage detection function after heat is regenerated, for avoiding any hidden peril. There is also a fuel gas leakage alarm device for real-time monitoring of gas concentration outside the tanks.

Thanks to the use of tubular heater, electrostatic protection device and nitrogen gas regeneration process, the risk of explosion of equipment is reduced to a maximum.

Product Specifcations

Type | Purifying Capacity | Heating Power |

YQJ-10N | 10 | 18 |

YQJ-15N | 15 | 18 |

YQJ-20N | 20 | 24 |

YQJ-30N | 30 | 24 |

YQJ-40N | 40 | 36 |

YQJ-50N | 50 | 36 |

YQJ-65N | 65 | 36 |

YQJ-80N | 80 | 54 |

YQJ-100N | 100 | 54 |

YQJ-150N | 150 | 72 |

Pre

Quenching Press

Next

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry