Nitriding Furnace Production Line

Widely applicable for nitriding treatments of various products, including hydraulic components, wind turbine gear rings, engine crankshafts, mold surface enhancement, clutch friction plates subjected to nitriding, and corrosion-resistant nitrided parts. It can achieve nitriding and soft nitriding processes tailored for a range of applications, such as hard nitriding, soft nitriding, and post-oxidation treatments.

Classification:

Products

keywords:

Hotline:

E-mail:

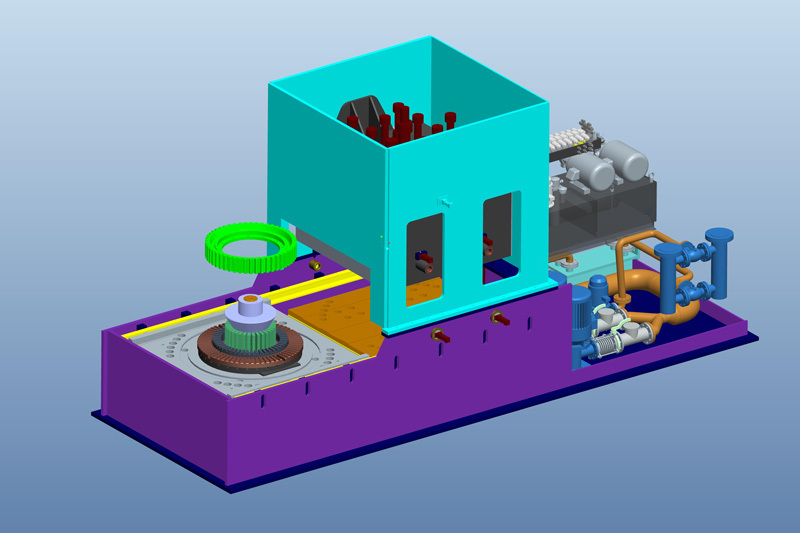

Nitriding Furnace Production Line

Equipment Introduction:

Multiple furnace types are available, including box-type nitriding furnaces, well-type nitriding furnaces, and hood-type nitriding furnaces, suitable for various products and operating conditions.

Widely applicable for nitriding treatments of various products, including hydraulic components, wind turbine gear rings, engine crankshafts, mold surface enhancement, clutch friction plates subjected to nitriding, and corrosion-resistant nitrided parts.

It can perform nitriding and soft nitriding for various products, including hard nitrided, soft nitrided, and post-oxidized components.

The selection of different furnace types and specifications allows for flexibility, catering to both multi-variety, small-batch production as well as single-variety, large-scale manufacturing. It also enables the nitriding treatment of various large components, including extra-wide and extra-long parts. We accept non-standard customizations to meet specific customer requirements, while providing optimal solutions that balance product quality assurance with reduced operational costs.

Product structure and features:

● Box-type Nitriding Furnace:

- Series-based design with multiple product specifications available, offering furnace loading capacities ranging from 600 kg to 3,000 kg across a standardized series.

- Available in two specifications: with or without a canister, depending on usage conditions.

- It can be integrated with a feeding station, cleaning machine, pre-oxidation furnace, and material carts to form a nitriding furnace production line, enabling fully automated operation.

- It can also operate independently as a single unit.

- Can be equipped with a pre-vacuum function for rapid air exchange.

- Electric heating and gas heating options available.

- Equipped with a quick-cooling function, it enables rapid temperature reduction, refines tissues, and boosts production efficiency.

- Utilizing a mass flow meter to control the nitrogen potential, ensuring precise regulation of the nitrogen level.

- It can be equipped with a three-position stainless steel vacuum cleaning machine to enhance cleaning performance and reduce workers' physical strain.

- Centralized control system for comprehensive monitoring and recording throughout the entire process.

- Multiple nitrogen potential control systems available.

● Well-type Nitriding Furnace:

- Series-based design offers a variety of specifications, ranging from small to large sizes, with the maximum effective diameter reaching up to 4 meters.

- Can be equipped with a pre-vacuum function for rapid air exchange.

- Electric heating and gas heating options available.

- The equipment features a large loading capacity, a simple and reliable structure, high safety, and relatively low operating costs.

- Equipped with a quick-cooling function, it enables rapid temperature reduction, refines tissues, and boosts production efficiency.

- Utilizing a mass flow meter to control the nitrogen potential, ensuring precise regulation of the nitrogen level.

- Customized non-standard solutions can be provided based on product requirements.

● Enclosure-Type Nitriding Furnace:

- Series-based design offers a variety of sizes, ranging from small to large, with the maximum effective diameter reaching up to 3 meters.

- A dual-stove-top structure, designed with both a heating cover and a cooling cover. This setup allows one stove to be in production while the other is on standby, sharing the same heating and cooling covers.

- Loading is done from the ground, making it convenient for workers to operate, and ideal for the nitriding treatment of large gear rings.

- Utilizing a mass flow meter to control the nitrogen potential, ensuring precise regulation of the nitrogen level.

- Customized non-standard solutions can be provided based on product requirements.

Pre

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry