Rotary Hearth Furnace Heat Treatment Line

Rotary Hearth Furnace is a high-capacity system suitable for treating per cycle a large batch of work pieces. It features the use of a single access door for loading and unloading of work pieces, the work pieces rotate with the base,and the work pieces can be loaded in furnace in an either single or multi-layer mode.

Classification:

Products

Hotline:

E-mail:

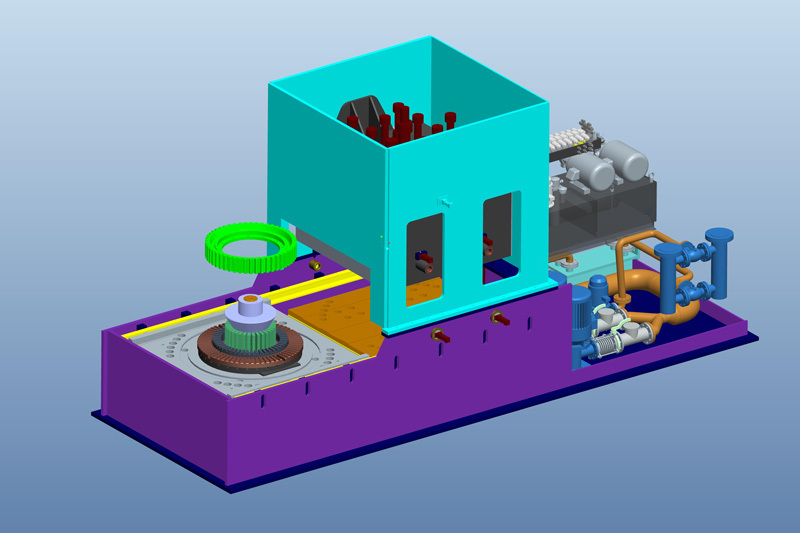

Rotary Hearth Furnace Heat Treatment Line

Product General Description

Rotary Hearth Furnace is a high-capacity system suitable for treating per cycle a large batch of work pieces. It features the use of a single access door for loading and unloading of work pieces, the work pieces rotate with the base,and the work pieces can be loaded in furnace in an either single or multi-layer mode. The work pieces turn round along with the rotating furnace bottom, and protective atmosphere is used for heating. The line is extensively used for carburization, carbonitriding, scale-free heating of clutch gear rings, spiral bevel gears, bearing rings, and gears pressure quenching, mar quenching and bainite quenching can also be effected when the line works in combination with pressure quenching machine, water tank, oil tank or salt tank. The line has found widespread applications in sectors manufacturing auto parts or bearings.

Product Structure and Character

The furnace chamber is round in design. It ofers the merits of being less in occupation of foor space, compact in layout and high in efciency.

The work pieces are loaded and unloaded via a single access door by means of easy-to-operate manipulator.

Thanks to the use of uniformly distributed radiation tubes, large-capacity circulating fans and high-accuracy temperature control instruments, the furnace temperature is high in uniformity.

The system is provided with touch-screen computer. It is easy to operate and is capable of continuously recording the operating data for easy inquiry.

A series of the furnace is available for selection (The maximum efective diameter of the furnace is 4.5m).

It can be equipped with pressure quenching transfer manipulator or robot, as well as quenching press to provide a full set of converter pressure quenching line.

Product Specifcations

Type | Hearth Dia. | Cycle time | Working Stations |

RE9-170-SP | 1700mm | ≥45s | As needed |

RE9-230-SP | 2300mm | ≥45s | As needed |

RE9-270-SP | 2700mm | ≥45s | As needed |

RE9-350-SP | 3500mm | ≥60s | As needed |

RE9-450-SP | 4500mm | ≥60s | As needed |

Pre

Flame-retardant Dust Purification System

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry