Pit Furnace Heat Treatment Line

The controlled atmosphere pit carburizing furnace line is generally composed of pit carburizing furnace, pit tempering furnace,quenching oil (salt) tank, cleaning machine, etc.

Classification:

Products

keywords:

Hotline:

E-mail:

Pit Furnace Heat Treatment Line

Product Overview

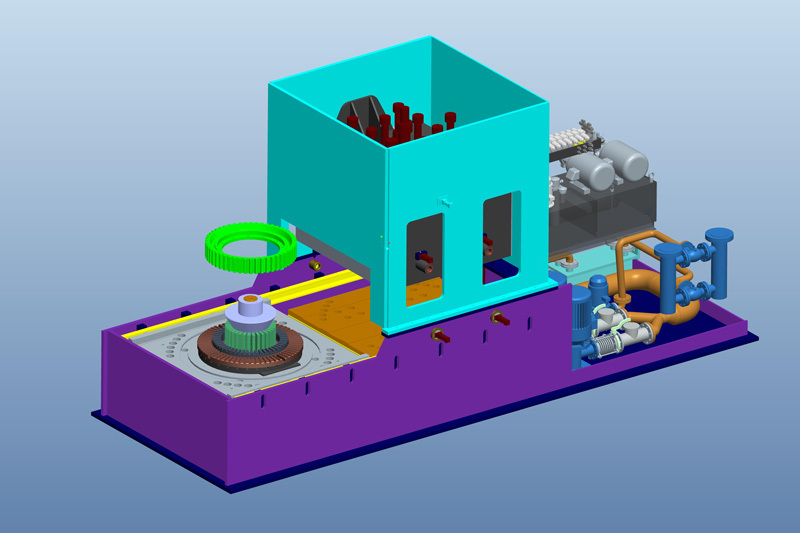

The controlled atmosphere pit carburizing furnace line is generally composed of pit carburizing furnace, pit tempering furnace,quenching oil (salt) tank, cleaning machine, etc. The equipments specifications and quantity can be flexibly configured according to the actual needs of customers. It's suitable for heavy duty gear, large bearing and other workpieces of carburizing, quenching, tempering and other heat treatment process.

Controlled atmosphere pit nitriding furnace has the functions of pre-vacuum, pre-oxidation, post-oxidation and so on,and can be used for nitriding and carbonitriding of various specifcations of products.

Product Structure and Character

600-1500mm

1-10 meters

0.5–0.6 tons

A variety of furnace types to be choose, and non-standard design can be provide. The effective diameter is 600mm-5000mm, the efective depth is 1-10m, and the loading capacity is 0.5ton-60 tons.

Optimized thermal insulation structure: the customized nano thermal insulation materials were added to the side wall of the furnace to obtain signifcant energy saving efect.

The retort can be designed with bottom , with an oil seal, or with an expansion joint.

The pit carburizing furnace can be designed with/without retort to meet different process requirements.

Electric or gas heating is available.

A variety of atmosphere control methods are optional.To effectively ensure the stability of the furnace atmosphere composition the process gas fow can be monitored, recorded and controlled.

The lifting mode of furnace cover is hydraulic arm type or gantry type.

The process information as temperature, carbon potential, process gas flow, pressure and process can be recorded and can realize the centralized management of workshop or factory through communication with user's MES system.

Oil quenching tank can be matched with fire resistance fue gas purifcation system to improve the working environment of the workshop.

Product Specifcations

Type | Efective working space | Max. load |

RFT9—160×200—SP | ⊘1600×2000mm | 10000kg |

RFT9—160×400—SP | ⊘1600×4000mm | 20000kg |

RFT9—200×200—SP | ⊘2000×2000mm | 16000kg |

RFT9—200×400—SP | ⊘2000×4000mm | 35000kg |

RFT9—250×250—SP | ⊘2500×2500mm | 35000kg |

RFT9—300×250—SP | ⊘3000×2500mm | 40000kg |

RFT9—350×250—SP | ⊘3500×2500mm | 50000kg |

RFT9—400×250—SP | ⊘4000×2500mm | 55000kg |

RFT9—500×250—SP | ⊘5000×2500mm | 60000kg |

Pit type nitriding furnace has the same specifcation.

All furnace types can be customized according to the needs of customers.

Pre

Box Furnace Heat Treatment Line

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry