Pusher Furnace Heat Treatment Line

Pusher furnace is used in the heat treatment of gear, bearing, crankshaft and other auto parts, such as carburizing, carbonitriding, tufftriding, or protective atmosphere heating and quenching.

Classification:

Products

keywords:

Hotline:

E-mail:

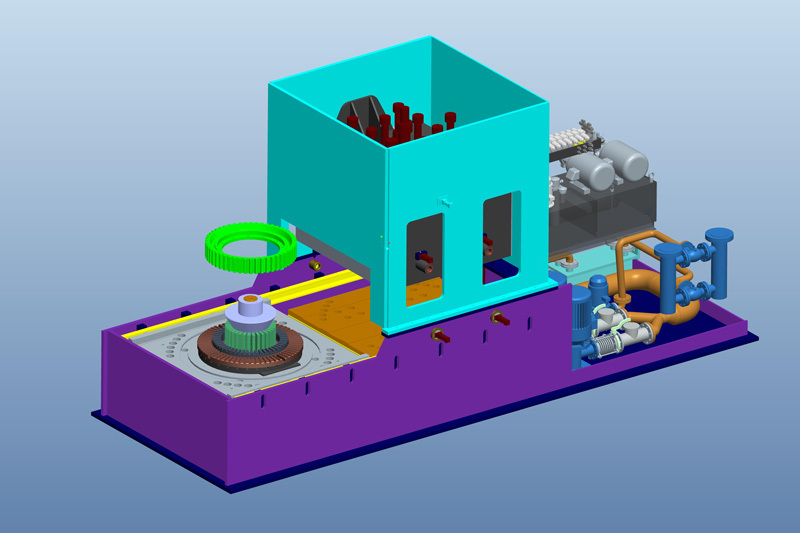

Pusher Furnace Heat Treatment Line

Product General Description

Pusher furnace is used in the heat treatment of gear, bearing, crankshaft and other auto parts, such as carburizing, carbonitriding, tufftriding, or protective atmosphere heating and quenching. Heating method for electric heating or gas heating.Quenching medium can be mineral oil or nitrate. To meet your different requirements, we can also provide multi-process pusher furnace production lines.In one line,the processes including direct quenching, pressure quenching and bainite hardening.

Product Structure and Character

Modular design for fexibility and ease of maintenance.

The dual-pusher furnace allows for the concurrent production of two types of products with distinct infltration layers within the same furnace.

Silicon carbide and high alumina segmented skid rails.

Optimized thermal insulation structure: the customized nano thermal insulation materials were added to the side wall of the furnace to obtain signifcant energy saving efect.

Single or multiple quench systems (oil, water, polymer or molten salt).

Various kinds of atmospheres can be used, viz: nitrogen, methanol+propane (acetone+natural gas) and propane (acetone) +air or RX gas when gas generator is used. Can realize the fow display, record, out of tolerance alarm function.Double valve series design to prevent fammable gas leakage.

Plant Control System

Visible operation, interface friendly, process setting conveniently downloading.

Monitoring and recording the whole production process,tray info and process is traceable at any time and could be stored for more than 10 years, the high-end customer’s demand of products traceability could be satisfed.

Penetration layer simulation function provides reference data of penetration layer depth and carbon concentration distribution.

Developed with smart phone APP to realize real moving ofce, the authorized personnel of the buyer could monitor in distance online.

Pre

Roll-bottom annealing furnace

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry