Box Furnace Heat Treatment Line

Box furnace production line is the most widely used mature furnace type in heat treatment industry. The system is applicable for either mass or batch processing of various kinds of work pieces. It has a large scope of applicability and is particularly suitable for carburization, carbonitriding. recarburization, as well as oxygen-free heat hardening, normalization and annealing of complex parts under protective atmosphere.

Classification:

Products

keywords:

Hotline:

E-mail:

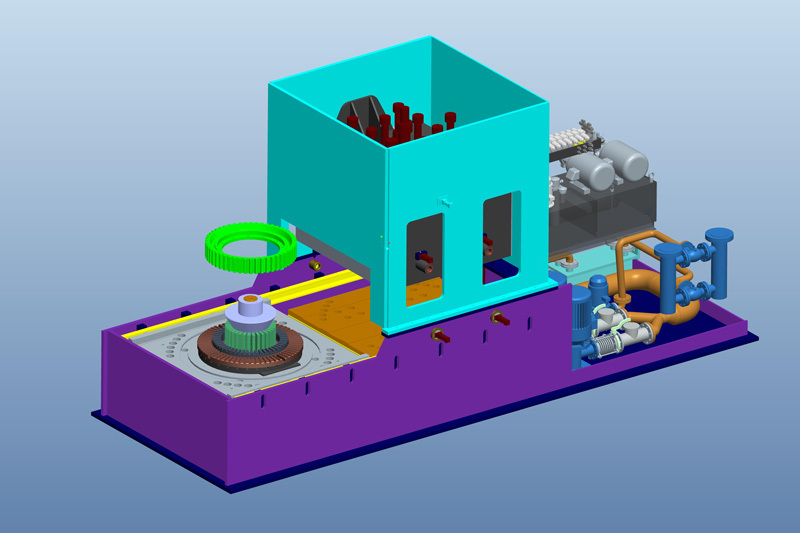

Box Furnace Heat Treatment Line

Product Overview

Box furnace production line is the most widely used mature furnace type in heat treatment industry. The system is applicable for either mass or batch processing of various kinds of work pieces. It has a large scope of applicability and is particularly suitable for carburization, carbonitriding. recarburization, as well as oxygen-free heat hardening, normalization and annealing of complex parts under protective atmosphere.

Product Structure and Character

Diferent kinds of series furnaces are available, with a maximum loading capability of 5 tons. The furnaces vary in types: single access gate or straight-through (selectable).

The rear chamber is optimized with additional heat insulation layer made of nano-material for efective reduction of heat loss.

Circulation of gas in furnace is efected by means of large-diameter circulating fan for ensuring the uniformity of temperature and atmosphere in furnace.

Furnace can be Electric heated or gas heated (selectable).

Various kinds of atmospheres can be used, viz: nitrogen, methanol+propane (acetone+natural gas) and propane (acetone) +air or RX gas when gas generator is used. Can realize the flow display, record, out of tolerance alarm function. Double valve series design to prevent fammable gas leakage.

The washing machine is provided with mobile high-pressure nozzles to ensure its product surface is thoroughly cleaned with no point left un-cleaned.

Avariety of quenching media options: oil quenching, salt quenching or water based quenching, the oil tank is large in volume and is provided with powerful, frequency controlled mixer and special flow deflection mechanism. This permits an even cooling effect, reduced quenching-induced deformation of work-pieces and the formation of nonmartensitic surface.

Upper computer system and control system: using computer + touch screen control system, infltration layer ofine simulation online real-time display, with automatic control, full data recording, and designed with MES system interface, convenient centralized management for customers.

Product Specifcations

Type | Efective working space | Heating power | Max. load |

RMT9-60/65/110-SP | 1100x600x650mm | 105kW | 650kg |

RMT9-70/65/130-SP | 1300x700x650mm | 105kW | 1000kg |

RMT9-70/85/130-SP | 1300x700x850mm | 142kW | 1200kg |

RMT9-70/105/130-SP | 1300x700x1050mm | 142kW | 1200kg |

RMT9-90/65/150-SP | 1500x900x650mm | 135kW | 1200kg |

RMT9-90/85/150-SP | 1500x900x850mm | 144kW | 1500kg |

RMT9-90/105/150-SP | 1500x900x1050mm | 166kW | 1800kg |

RMT9-120/90/150-SP | 1500x1200x900mm | 166kW | 1800kg |

RMT9-90/85/180-SP | 1800x900x850mm | 190kW | 2500kg |

RMT9-120/85/180-SP | 1800x1200x850mm | 260kW | 3500kg |

RMT9-120/115/180-SP | 1800x1200x1150mm | 260kW | 4500kg |

Pre

Nitriding Furnace Production Line

More products

Roller-hearth Salt Bath Quenching Heat Treatment Production line

Pusher Furnace Heat Treatment Line

Pit Furnace Heat Treatment Line

Box Furnace Heat Treatment Line

Nitriding Furnace Production Line

Fully-automatic clutch Diaphragm Spring (Disc Spring) Press Quenching Line

Rotary Hearth Furnace Heat Treatment Line

Flame-retardant Dust Purification System

Smoke and Dust Purification System

Industrial Gas Deep Purification Equipment

Provide heat treatment equipment solutions for your industry